Get Support

- General Inquiries

- Technical Support

- FAQ

- Browse Knowledge Base

- How-to Videos

- View an Owner's Manual

Phone

- +1 (231) 221-0104

Choosing the Right Underground Pipe for Your System

There are lots of options available when it comes to installing the underground pipe for your outdoor wood furnace. Sectional or seamless, foam or foil wrapped, the right underground piping can make a huge difference in how effective your outdoor wood furnace operates.

It wasn’t too long ago that insulating underground pipe was timely and very expensive. To save on cost most homeowners turned to 10 foot sections of insulated 4 inch PVC pipe that had already been available on the market for other specialty plumbing needs. The outside of each pipe was insulated and wrapped with a plastic bag material. Long pieces of pex or pex-al-pex pipe were fed through these sections of 4 inch pipes. After threading each section the pipes would be glued and sealed using tape. The job was awkward, difficult and labor-intense. Sealing each section proved to be nearly impossible and the pipe would fill with water, causing major heat losses and ruining any advantage of an outdoor wood furnace.

Other sectional pipes have also come onto the market but they all have the same basic flaw, seams underground. The flexible foam variety not only lack adequate insulation value but are susceptible to water penetration through each and every joint underground.

Modern underground pipe lines for outdoor wood furnaces have many advantages; namely, there are no seams buried under the ground. Even within this seamless category there are advantages and disadvantages.

Most manufacturers use pex pipe in their construction (see Pex vs. PAP). Foam filled varieties seem to be the best alternative but a deeper investigation proves that foam isn’t always the answer.

First, foam insulated underground piping is almost always 1 inch pex. As discussed in a previous article 1 inch pex carries far fewer BTU's than pipe with a true 1 inch inside diameter such as Pex-al-pex pipe. Expansion should also be taken into account. 100 feet of underground pex heated up to 180°F will expand 6 to 7 inches lengthwise. This puts pressure on fittings and may cause leaks or failures.

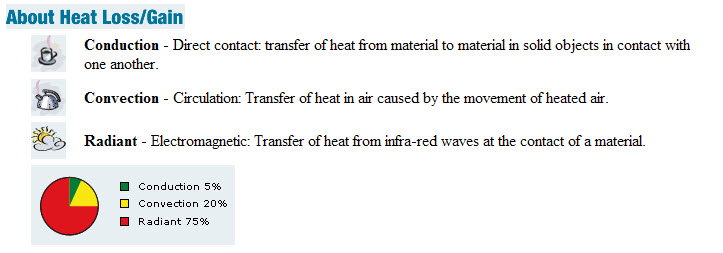

The insulation itself should also be considered. Piping used for supplying heat from a hot water source, such as an outdoor wood furnace, lose heat in 3 ways: Convection, Radiation and Conduction. Convection is air moving across a surface similar to a radiator or heat-sync. Radiation is heat moving from hot to cold, like we all learned about in high school physics. Conduction, related to convection and radiation has to do with how heat moves through materials like air, foam or metal (electrical wiring).

Convection doesn’t apply when outside air is sealed off. R-value, a measure of convection, means little when convection is absent.

Radiant heat loss is the most relevant when speaking of underground insulated pipe. We’ll return to this shortly.

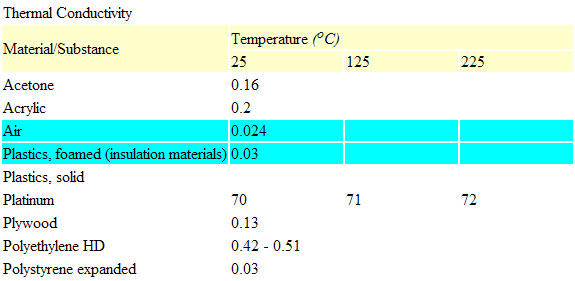

Conduction, heat transferred away by the materials surrounding it, is best controlled by wisely choosing the proper materials for insulation.

Foam filled underground pipe use urethane-based foams that limit heat loss based strictly on R-value, trying to limit how much heat is lost to convection. Foams only limit radiant heat loss by absorbing heat in a slightly limited way.

The best choice for underground lines is a pipe incorporates both foam and foil wrapped insulation. The foil wrapping retains over 97% of the radiant energy back into the pipe, virtually eliminating heat loss. Foil wrap must be contained. Strong, flexible corrugated pipe provides a shell of protection for the foil wrap and also creates a space of dead air that serves as a conductive break. Having the correct corrugated pipe is important, too stiff and it will crack when bent or compressed, too thin and it may be pierced by rocks or other sharp objects in the ground. After installation this type of underground pipe, expanding foam is used on each end to seal the air space, eliminating heat loss by convection.

Hawken Energy carries Heat-Miser foam/foil-wrapped pex-al-pex underground pipe through our Factory Rep network and through our online store. Heat-Miser pipe is recommended for all Hawken Energy installations. It is available in rolls 250 feet long and can be cut to length for your installation at increments of 25 feet.

Searchable keywords: underground, pipe, foam, foil wrapped, piping, insulating